3D Printing Master Guide 2025

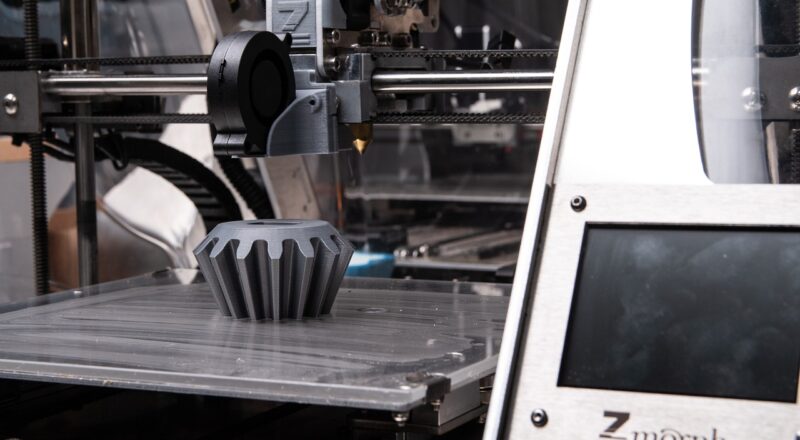

The three-dimensional (3D) printing, an additive manufacturing technique, creates physical objects using a digital image. The method works by spreading thin layers of material made of powdered or liquid plastic, cement, or metal, after which these layers fuse to form a solid layer.

Understanding 3D Printing

Since its introduction 3D printing process has significantly increased efficiency of manufacturing. Longterm 3D printing could be used to alter manufacturing logistics as well as managing inventory industries specifically when it is effectively integrated into manufacturing methods.

The speeds of 3D printing currently arent fast enough to use in massive production. But it is being used to cut down delay when it comes to design prototypes for parts as well as devices and also equipment needed to manufacture these.

This can be extremely beneficial for smallscale companies because it decreases their expenses and period from conception to launch which is period of time it takes from moment product is beginning to be designed until it is sold.

3D printing allows for creation of complex and intricate shapes with much less material than subtractive manufacturing methods like welding drilling molding and many other methods. ability to create prototypes quicker simpler and more affordable allows greater innovation exploration as well as productbased startup.

Why Are 3D Printers Important to Future?

The flexibility speed and accuracy of 3D printers makes printers powerful tool to manufacturing in near future. In present lot of 3D printers are employed in whats called Rapid prototyping.

All kinds of businesses around globe use 3D printers for creating their models in just couple of minutes rather than spending months and perhaps millions of dollars spent on process of research and development. Indeed some companies declare that 3D printers can make prototyping process 10 times more efficient and 5 times less expensive over traditional R&D procedures.

3D printers are able to play function in almost any business. Theyre not only used to create prototypes. lot of 3D printers are assigned to print finished items. construction sector uses latest printing technology to print entire homes.

Schools across globe utilize 3D printers that bring interactive education to classrooms by printing threedimensional dinosaur bones as well as robotics components. versatility and flexibility of 3D printing makes it an essential tool for anyone in business.

How Does 3D Printing Work?

All it takes is an 3D model. It is possible to build your own from scratch or download model from library of 3D models.

3D Software

There are numerous tools that are available in software. overview we’ve put together is on 3D Software website.

It is recommended for beginners to begin with Tinkercad. Tinkercad is available for free and operates within your browser. You arent required to download it onto your PC. Tinkercad provides beginnerlevel lessons as well as builtin option to save your model in an image file that can be printed e.g .STL as well as .OBJ.

Once youve got file with printed layout then next thing to do is to set it up to be printed by 3D printer. This is known as cutting.

Slicing: file onto 3D Printer

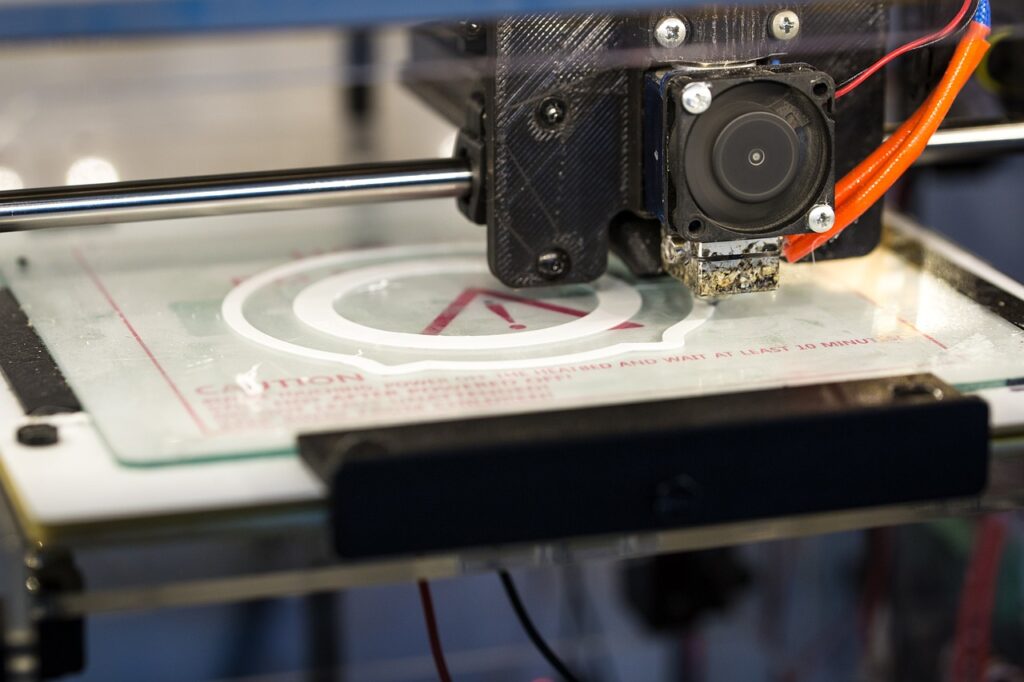

Slicing simply means cutting 3D model into thousands or hundreds of layers. This is achieved using cutting software.

After your file has been sliced and ready to go into 3D printer of your choice. transfer of file to printer is possible through USB SD or WiFi. file you cut is in process of being 3D printed layerbylayer.

3D Printing Industry

The adoption of 3D printing has hit point of critical mass and people who are yet to incorporate additive manufacturing into their supply chain are part of shrinking percentage. While 3D printing was appropriate for prototyping or oneoff manufacturing at beginning technology is rapidly becoming ultimate manufacturing technology.

The majority of need of 3D printing is industrialrelated. Acumen Research and Consulting forecasts 3D printing industry worldwide to grow to $41 billion by 2026..

As technology develops technology of 3D printing will revolutionize almost all major industries.

3D Printing Process

Once modeling and slicing of an 3D object has been completed then its time to allow it to be time for 3D printer to assume role of printer. printer functions similar to conventional printing device in inkjet 3D printing procedure in which nozzle rotates between two directions in process of dispensing wax similar polymer layer by layer and waiting for it to dry before creating next layer. It basically puts thousands or hundreds of 2D prints over each other to create an object that is threedimensional.

3D Printing Materials

There is wide range of printing materials to reproduce something to very best of its capabilities. Below are few examples of:

- Acrylonitrile Butadiene Styrene (ABS) plastic material which is simple to form and is tough to crack. It is same plastic that LEGOs are built from.

- Carbon Fiber Filaments: Carbon fiber is utilized to make items that must be extremely durable yet very light.

- Conductive Filaments: These printed materials are currently in testing phase and are printed with electrical circuits without need to use wires. It is an excellent material to wearable technology.

- Flexible Filaments: Flexible filaments print prints that can be bent and yet durable. Flexible filaments can be used for printing anything from watches and phone covers.

- Metal Filament : These filaments are composed from finely ground metals as well as polymer glue. They come in different forms like form of bronze steel brass and copper in order to capture exact texture and appearance of metal objects.

- Wood Filament : These are filaments that comprise finely ground wood particles blended with polymer glue. It is utilized to print woodlike objects that look similar to light or dark wood based on temperature of your printer.

The process of 3D printing can take up to few hours for prints that are really basic such as ball or box balls up to weeks or weeks to print more elaborate projects like fullsized house.

Examples of 3D Printing

3D printing covers variety of technology and materials. 3D printing is used in every industry one could imagine. It is important to view it as an amalgamation of various industries with many different uses.

Some examples:

- consumer products (eyewear footwear design furniture)

- Industrialrelated product (manufacturing tools prototypes functional endofuse components)

- dental care products

- prosthetics

- architectural scale models & maquettes

- reconstructing fossils

- Replicating antiquated artefacts

- reconstruction of evidence from field of forensic pathology

- movie props

Consumer Products

We first began blogging on 3D printing in 2011 3D printing wasnt ready to use in production processes for huge quantities. There are now lot of examples of finaluse 3D printed products for consumers.

Footwear

Adidas”4D” collection has full 3D printing of its midsole and it is currently being produced in huge volumes. We wrote an article in past in which we explained process of how Adidas had initially released just 5500 pairs of their shoes available to public.

Read more: Decentralized Identity in 2025: Revolutionizing Digital Identity Management

Read more: GPU? Master Guide to Graphics Processing Unit 2025

Read more: Best Microlearning Platforms for Quick Upskilling

Company was planning to sell 100000 pairs of AMinfused models by year 2018.

The latest versions of footwear It appears that they have achieved their goal or are close towards achieving goal. sneakers are readily available throughout world through local Adidas shops as well as via various online 3rd party stores.

Eyewear

The market for 3D printed glasses is predicted to be $3.4 billion in 2028. One of fastestgrowing segments is enduser frames. 3D printing is most ideal method for making glasses for eyes because measurements of an individual are straightforward to use in final products.

Did you know that its possible to also 3D print lenses? Glass lenses traditionally dont start from thin and light theyre made from more substantial block of material referred to as blanks around 20% of which is sent into waste.

If we look at amount of glasses worn by people and how frequently theyll need to purchase new glasses we can see that majority of that can be considered waste. In addition labs must keep large inventories of glasses in order for particular prescriptions of their clients.

In end 3D printing has developed enough to allow for highquality customized ophthalmic lenses. This means doing all waste and costs associated with inventory in earlier.

Luxexcels VisionEngine 3D printer makes use of an acrylate monomer that is UVcurable that prints two pairs of lenses in an hour which do not require polishing or postprocessing.

The focus areas are able to be altered to point specific part of lens will give better clarity at distance while another region of lens will provide more clarity when you are close.

Jewelry

There are two methods of creating jewelry using help of 3D printer. It is possible to use either direct or indirect manufacturing procedure.

Direct is process of creating of product straight out of 3D pattern while indirect refers to fact that object (pattern) which is 3D printed later is then utilized to make an investment casting mold.

Healthcare

Theres no reason not to read about 3Dprinted implants. majority of these have been deemed experimental and cause it to appear that 3D printing is considered fringe technology in medical and healthcare industries However thats not really an issue anymore. In past 10 years over 100000 hip replacements were 3Dprinted with help of GE Additive.

DeltaTT Cup DeltaTT Cup designed by Dr. Guido Grappiolo and LimaCorporate is constructed from Trabecular Titanium which is distinguished by its regular threedimensional hexagonal cell structure which mimics trabecular bone morphology.

The trabecular shape improves biocompatibility and strength of titanium by encouraging growth of bone within implant. first DeltaTT implant are still well decade after.

A third 3Dprinted healthcare item which is capable of not being detected includes hearing aid. estimates are that 90% of hearing aids that are manufactured make use of technology of additive manufacturing. you can see reason.

Dental

- Within dental sector there are molds made for clear aligners as perhaps largest 3D printed objects around globe.

- Molds currently are printed 3D using both powder and resinbased 3D printing methods as well as using material jetting.

- Dentures and crowns are direct 3D printed along surgical guides.

Bioprinting

Since beginning of time 3D printing has been investigated by biotech companies and academics for its potential use in applications of tissue engineering that involve body organs and parts are constructed with inkjet technologies.

Living cells are placed on gelbased medium that is then gradually constructed to create threedimensional designs. subject using word: bioprinting.

Food

Manufacturing with additives entered manufacturing in sector of food quite while in past. Restaurants such as Food Ink and Melisse use additive manufacturing as distinct selling point in order to entice patrons from around globe.

Education

Students and teachers have used 3D printers in classrooms. 3D printing allows students to create their concepts with ease and costeffective method.

While additive manufacturingspecific degrees are fairly new universities have long been using 3D printers in other disciplines. There are numerous educational classes you can choose to take that will help you get acquainted in 3D printing. University courses cover subjects related to 3D printing such as CAD as well as 3D design. This are applicable to 3D printing in particular level.

For prototyping purposes universities are increasingly making use of printers. Specializations are available in additive manufacturing that one could achieve through industrial or architectural design degree programs. Prototypes printed with printer are frequent in field of arts of animation fashion and fashion studies too.

Advantages of 3D Printing

3D Printers Are Affordable

3D printing has capability of making production process for complicated parts easier due to use of computer programming. It is often an affordable alternative for certain industries.

Another factor that influences price of 3D printing is material employed. 3D printing is able to make use of inexpensive concrete and plastic that are readily available. Furthermore as theres no requirement for molds when it comes to 3D printing its an additional expense eliminated.

3D Printers Are Fast

3D printing is great option to quickly prototype products since it can be printed inhouse in smaller run. It allows companies to sort out any issues and then make modifications to their products more quickly than normal production procedure. Modifications to products are able to be created using CAD and cost of manufacturing remains exact.

3D Printers Can Work With Speciality Materials

- While metals and plastics are frequently utilized for 3D printing business however there is variety of different options to select from.

- It is advantageous because specific items and parts can be created using particular substances like waterabsorbing plastic titanium gold as well as carbon fiber.

- Specific materials such as these permit properties such as extreme temperature resistance water repellency and durability.

Disadvantages of 3D Printing

3D Printers May Not Provide Enough Strength

One disadvantage of creating an object layerbylayer is that this could affect strength and durability of item. Durability and strength of 3D printing is heavily dependent on materials utilized; concrete and metallic are always among most robust materials for 3D printing.

3D Printers May Have Accuracy Issues

- While CAD can be an efficient and reliable method to design there could have errors.

- accuracy of 3D printing is contingent on printing techniques and printers that you make use of.

- In particular small 3D printers like desktop printers be damaged easily. That means that as process of creating design progresses product created later could differ from original batch.

3D Printers May Require PostProcessing

- A further drawback of 3D printing concerns amount of work that is required to finish product.

- process could include sanding smoothing an object out as well as heat treatment or even removal of support struts.

- postprocessing process of 3D printed objects can result in additional charges.

External Links

- Link to Tinkercad: https://www.tinkercad.com

- Link to Acumen Research and Consulting’s report on 3D printing: https://www.acumenresearchandconsulting.com

Get in Touch with SJ Articles

Read more: Learn a New Skill Fast with These Bite-Sized Courses

Read more: Must-Have Software for Remote Job Starters

Read more: How to Improve Focus with Digital Wellbeing Apps